Automation & Integrations

Post-Press Automation & Integrations

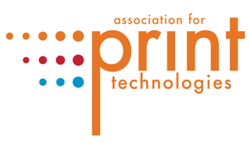

The experts at Rollem will listen to your production issues and then configure a print finishing solution to fill existing and future needs in your bindery department. We can integrate a Rollem with either your existing finishing machines or other products to remove the bottlenecks downstream and develop a streamlined system which results in less labor, greater job control and increased productivity.

We can automate your entire printing process, starting with a digital press sheet and converting it into a finished product ready for delivery to your customer.

Your press, UV coater, or folder/gluer system can seamlessly feed products to our Slitting, Scoring, Perforating, Die Cutting, Kiss Cutting, Fold/Glue or Collating units to create a print/coat/cut/finish system that eliminates manpower, stock movement, and excess waste, increasing production uptime and your bottom line profits.

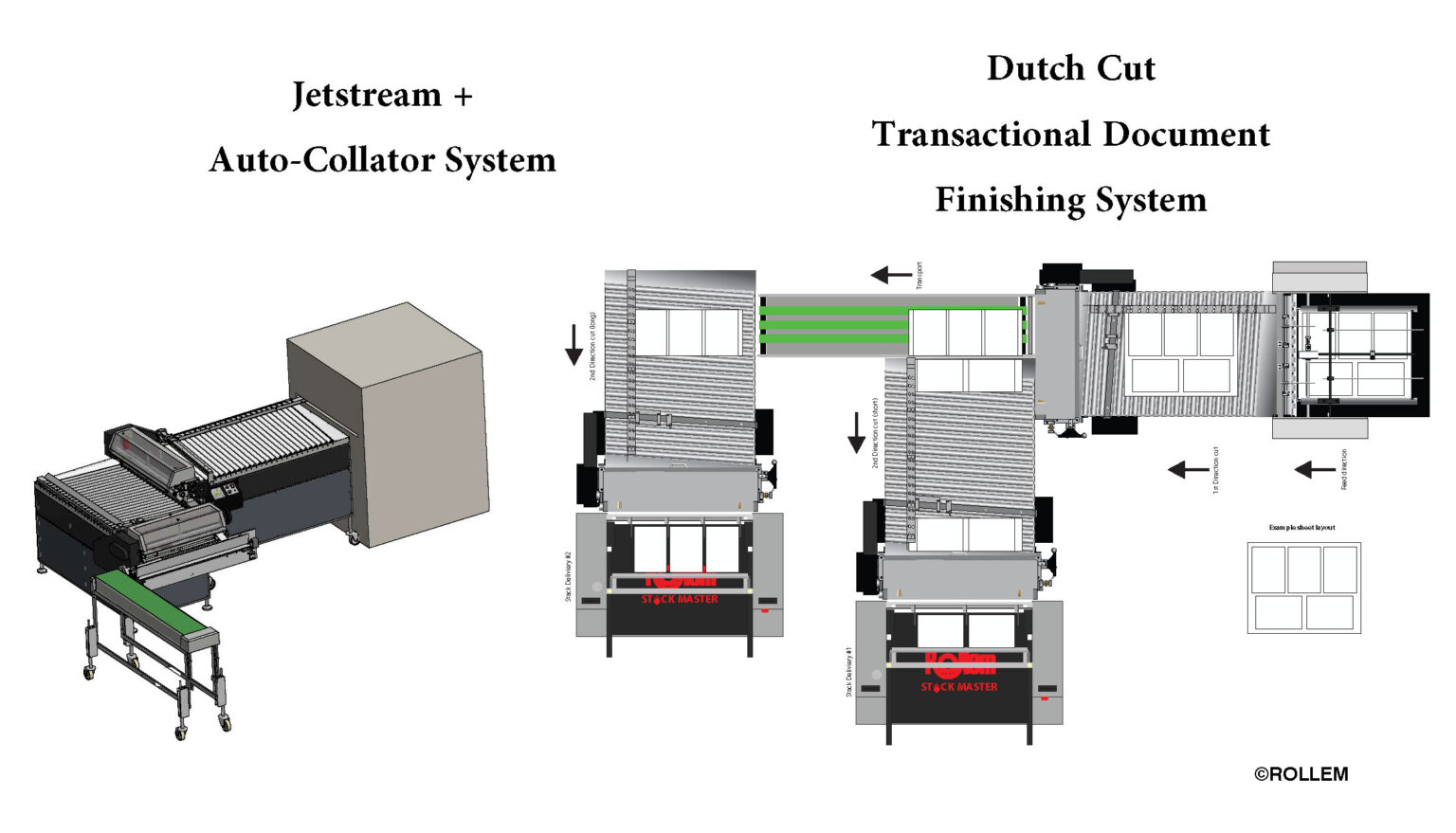

For example, Rollem’s Jetstream is ideally suited for operating in-line or near-line with HP Indigo, KM, Xerox, Ricoh, and other digital presses. Our TR model is designed for larger press sheets including 30” and 42” sizes.

Inline with Digital Press

Inline with UV Coater

Modular Design for Finishing Ease

In addition to in-line machine configurations which are ideally suited for higher volume dedicated runs, Rollem machines are built with a modular design, so they function equally well in near-line set-ups when positions close to the press to handle a variety of finishing jobs.

Whether your needs fall into a common configuration or you require a semi-custom set-up, our team welcomes the opportunity to discuss your specific situation and identify the correct finishing methods to complete your projects successfully.

Integrations include:

- Digital Presses

- UV Coaters

- Collating Machines

- Banding Machines

- Over Wrapping Machines

- Folding and Gluing Machines

- Bourg Sheet Feeders

- Round Cornering Machines

- Matrix/Skeleton Stripping Units